Sheet Metal Machinery Topics14. Nov. 2024 Space-saving, operate easily the new deburring machine DB1000H is launched!

|

|

Maximum sheet size |

Bengaluru International Exhibition Centre |

|---|---|

|

Machine size |

10th Mile, Tumkur Main Road , Madavara Post Dasanapura, Hobli, Bengaluru, Karnataka 562123 India |

|

Machine weight(kg) |

1300 |

|

Power supply(KVA) |

4.7 |

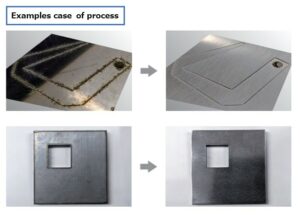

Deburring after forming and small bending operations, and removing the dross which happened at laser-cutting, are challenges for better manufacturing.

To address these challenges, Muratec has made comprehensive upgrades to the DB1000R,

by launching the DB1000H deburring machine, which offers a more compact design, greater energy efficiency, and utilizes the 4DD processing method.

1. compact design

Equipment size: length 1872mm, width 1419mm, height 1829mm, the total floor space of the equipment is about 2.65㎡!!

2. greater energy efficiency

In terms of power requirements, the DB1000H requires only 4.7kVA compared to 25.9kVA of the previous model DB1000S. (Both are not included dust collector)

3. Simple operation

The thickness measurement will check the thickness of the sheet, then this data value will be feeds to NC, and the old data will be overwritten by the value.

The operator just need to load the workpiece on the conveyor and press the "START" button to start processing.

4. Bar code management

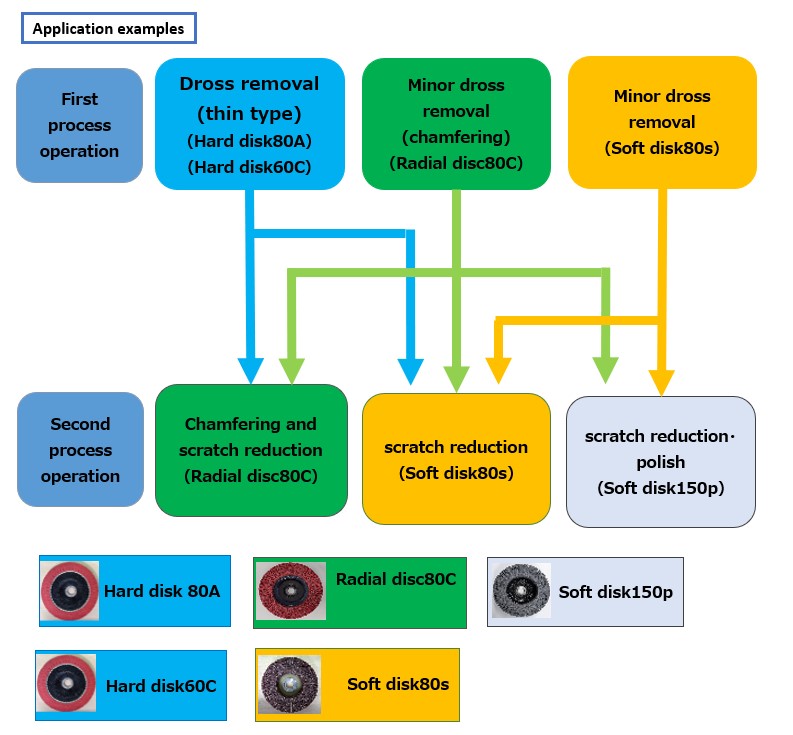

Manage the usage indication and the product life-time of the disk.

After scaning the barcode on the disk, then you press the button"?", the specification and feature information of the disk will be displayed.

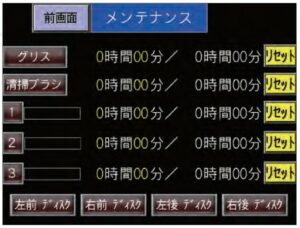

On the maintenance screen, by registering the management time or grease and cleaning brush in advance, you can do time management.

As for the discs, once the replacement timing will come, a red flash lighting will indicate the life-time completing.

5. Back side operation button

Operation button is located at the backside of machine. "Process stop, Emergency, conveyor feed speed".

Normally, operation is worked out on the front of the machine, but these buttons can be used when you want to take out the product quickly during trial production or single-piece processing,. And maintenance or trouble shooting time also will work by this buttun location.

6. Full open door for easy operation

Large folded doors is useful for approaching to machine. In case of the disk replacement and maintenance etc, full wilde open space is easy to access.